Eibach Replacement Line (ERL) Factory Replacement Springs

High-Quality OEM-Spec Replacements

- Development and production in Germany

- Made to OE guidelines (IATF 16949)

- Extensive references among car manufacturers and OEMs

- 70 years of experience as a spring manufacturer

- OEM's often use Eibach to produce their springs

70+ Years of Expertise

Eibach's quality promise starts with the careful selection of appropriate spring steels, which are formed on state of the art CNC winding machines with extreme precision. By combining heat treatment, shot peening and a durable corrosion protection, including powder coating guarantees durability and extreme stability. Each spring is set to block to ensure that after installation the vehicle remains at the correct ride height for thousands of miles.

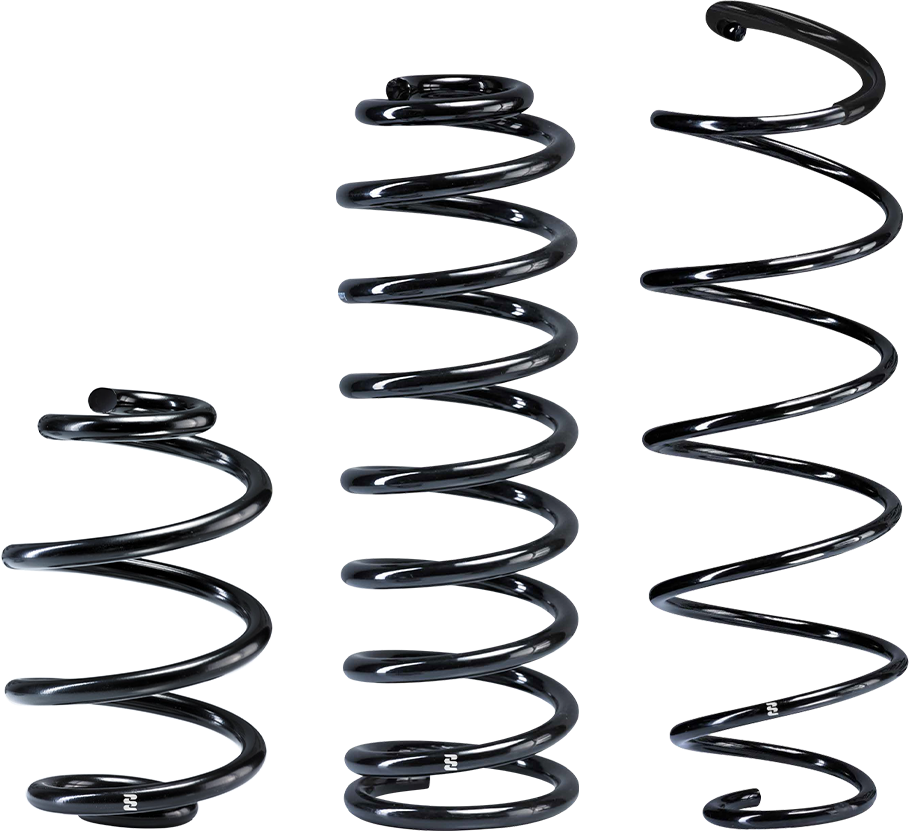

Cylindrical Springs

Cylindrical axle springs are probably the most classic design of coil springs and found primarily in double wishbone systems and related assemblies. Their windings are all equidistant from the imagined central axis of the spring in a horizontal line. In the linear design, the vertical spacing of the coil over the entire height is constant, which favors a homogeneous pattern over the full travel. In the progressive design, the distance between the windings over the entire length changes significantly. The goal is a comfortable suspension performance at low agitation in conjunction with a safe, sporty handling at stronger frequencies. A similar effect can also be achieved through its winding course by changing wire diameter. But regardless of how the vehicle designers have decided, Eibach covers the whole spectrum of standard replacement spring demand.

- Classical helical compression spring

- Centric center line (linear course of the center line)

- Often installed in double wishbone systems

- Linear or progressive spring characteristic

Mini Block Springs

Mini block springs are designed explicitly for the rear axle, where they can best leverage their strengths. This way it's extremely compact barrel shaped design allows the vehicle manufacturers more freedom in the planning of the luggage compartment. The coils are designed so that they can lie inside one another at high deflection without interference. In addition, they are constructed in their design to allow a comfortable ride without load, but offer a supreme handling at full load. Typical for this type of design is its progressive nature, which is not achieved by different winding distances, but only by an inconsistent wire diameter. Since mini block springs, unlike cylindrical springs, have a shorter life expectancy, Eibach has developed the concept which is optimized through the use of a cylindrical constant wire.

- Progressive spring characteristic

- Space-saving variant of the helical compression spring

- Mostly inconstant wire with tapered cross-sections

- No longer installed in new model generations because of low life expectancy

- increased service life due to optimized shape with constant wire diameter (when possible).

Side-Load-Springs, KMP-Springs

MacPherson struts are amongst the most common suspension systems in the car sector. Since the 1990s, side-load springs (SL) are being used more frequently. The arc-shaped springs are suitable to compensate transverse forces and also provide a number of advantages that make it suitable for other chassis structures. This way, SL springs develop a lateral force on the shock absorber in compression, which reduces the friction on the piston rod and seal, and thus prolongs its lifespan. At the same time, “arc springs” are very light therefore reducing the burden on all chassis components, and accommodates the modern lightweight thought. Also the response of the axis and the shock absorbers is optimized by SL springs, which gives the driver maximum control.

- Often used in MacPherson struts

- Compensation of transverse forces

- The line of action extends oblique to the damper axis in the unloaded state

- Develops a side force on the shock absorber in compression (reduces friction on the piston rod and seal of the shock absorber)

- Through the resulting force effect in deflection, driving comfort is increased